Published 10 March 2023

Share this story

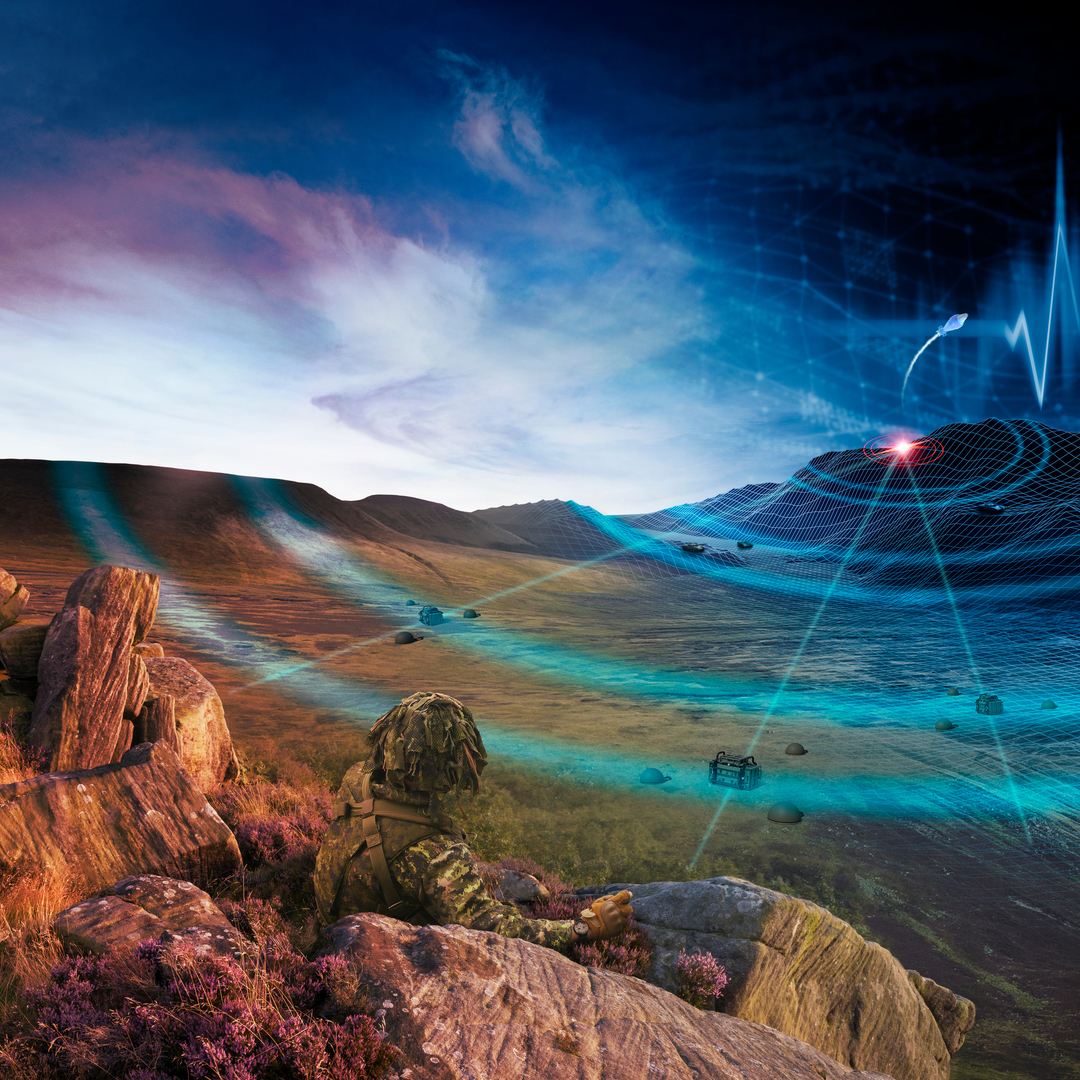

Advances in digital engineering are set to “revolutionise” defence procurement and support, ensuring the latest equipment makes its way from concept to the front line faster and more efficiently than ever.

Traditionally, when a new piece of equipment is required, it is a long, drawn out process of design and then prototype manufacture, which then undergoes months of physical testing – for example an aircraft in a wind tunnel to test aerodynamics.

With digital engineering however, the equipment can be digitally created – a “digital twin” – and virtually tested thousands more times than would be possible physically, boosting efficiency and vastly reducing costs without compromising safety.

“This technology is incredibly exciting as it will transform how we undertake our business to maintain the military advantage for our frontline Armed Forces, reducing both cost and time of defence acquisition,” said Stephen Wilcock, Director Engineering and Safety at DE&S.

“This is an opportunity to revolutionise how we work with industry so that, collectively, we can optimise capability at pace, enhancing interoperability and optimise support throughout the supply chain.”

Digital-led engineering and development approaches are already being used to great effect in industry across the world in efforts to reduce time and costs; DE&S is keen to tap into that experience and apply the latest approaches to the defence portfolio.

Adrian Baguley, Deputy Chief Executive at DE&S, said: “With this technology we can create a digital twin of the required equipment and, using AI and machine learning, digitally test it thousands of times generating all the data required to shape decision making and equipment acceptance in a fraction of the time.

“Not only is this a vastly more efficient and cost-effective way of working, most importantly it has the potential to super-charge the speed with which we can get vital equipment from the concept phase through to production and onto our frontline Armed Forces.”

He added: “Our industry partners are already making huge strides in this field and DE&S is committed to working closely with them to tap into this wealth of knowledge and capability.”